| Research project: | "ADAPT - Automatisierte Datenverknüpfung von der Auslegung bis zur Produktion" |  |

| Research area: | Umgebungsmodellierung, Location-Based Services, Assistenzsysteme, Automation | |

| Supported by: | BMWK in LuFo VI-1 | |

| In collaboration with: | Airbus Operations GmbH, Synergeticon GmbH, Deutsches Zentrum für Luft- und Raumfahrt e.V. (DLR), Zentrum für Angewandte Luftfahrtforschung GmbH (ZAL), Helmut-Schmidt-Universität, Institut für Technische Logistik, TUHH | |

| Start of project: | July 2020 | |

| End of project: | June 2023 |

Description:

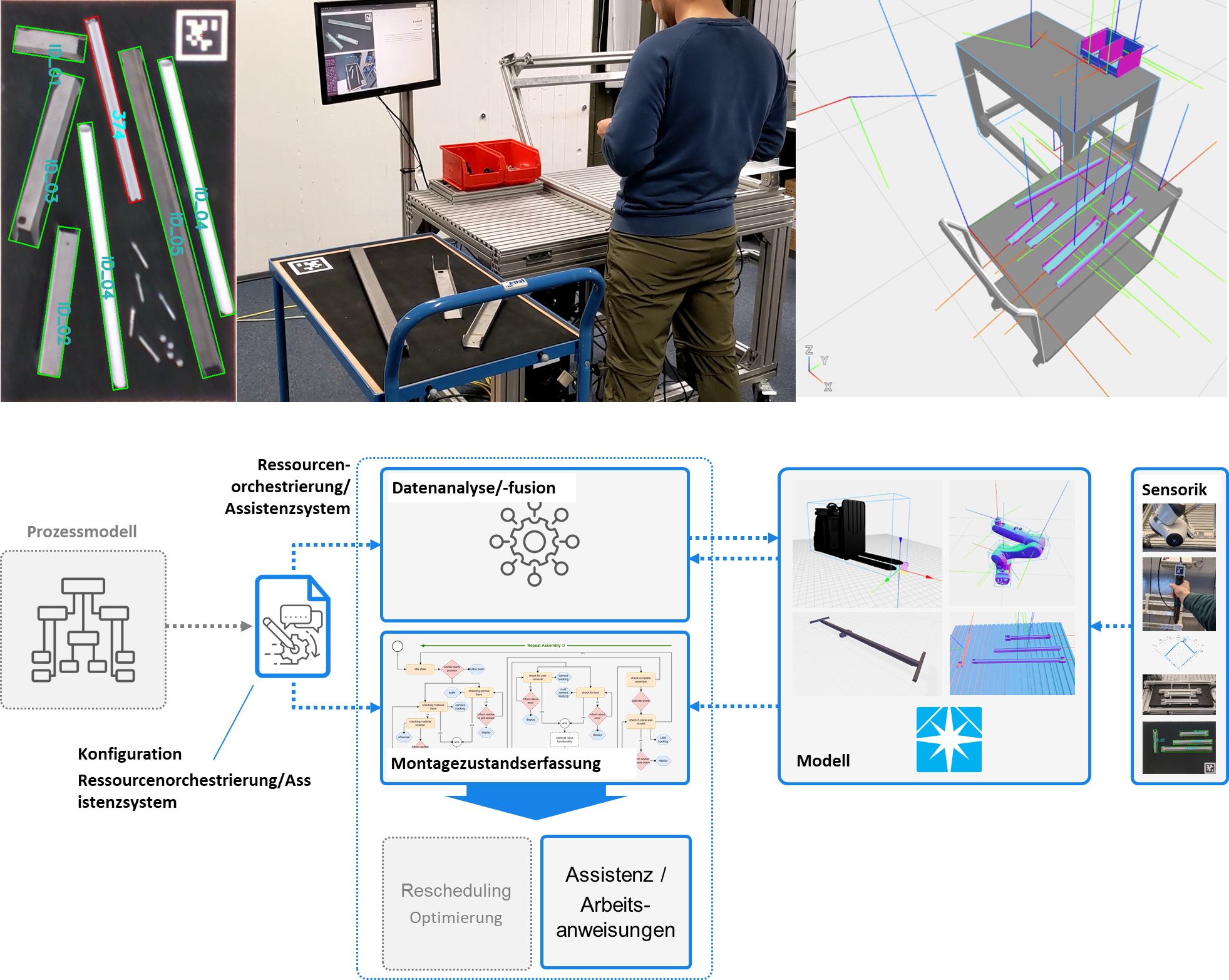

In the ADAPT20 joint project, the TUHH collaborated with the IFPT and ITL institutes in the sub-project "Feedback loops with production environment data and logistics model generator".

As part of Industry 4.0 and digitalisation, automated data management is to be developed as a complete chain from development to production in order to meet the special challenges of aircraft high-rate production. A fundamental component of this is the seamless integration of data and information across all stages of aircraft production, as is the primary objective of the ADAPT20 project.

The objective of the IFPT's involvement in the TUHH sub-project is to trace production environment data, utilizing a digital live representation of the environment, for utilization in both local and larger improvement cycles.

The data gathered from the production environment is incorporated into the live model of the environment and can be correlated with other production and location data from across domains, as well as operational data, to generate data of greater value. The data gathered from production can be utilized to achieve local enhancements in production, as well as in production preparation and design. The digital representation will serve as an interface between the process and resources, and, in ocmbination with provided work/assembly instructions, can be utilized for resource orchestration.

Upon completion of the project, The work and outcomes were demonstrated and validated through the implementation of an assembly assistance system.

Contact person at the institute: M.Sc. Arne Wendt